HQFO01 air jet loom is a high-end product launched by Tianyi Red Flag Textile Machinery, which can adapt to a wider variety fabric, especially for high-density and heavy fabrics, and has a qualitative improvement in operating speed and energy saving. The 190cm width operating speed can reach more than 1100 rpm, and more than 1000 rpm for 230cm width loom. Gas consumption can be reduced by 15% (production output), energy saving effect is remarkable! More high speed, more efficient, more energy saving, more intelligent HQFO01 air jet loom is a better choice of weaving equipment for textile enterprises!

1. The shape design highlights the cultural image of HQF Red Flag Textile brand. The blue shell on both sides of the front is like two weaving flags, which is not only two keys to wealth, but also the wings of career take-off. The arc transition line highlights the high-end quality of the product.

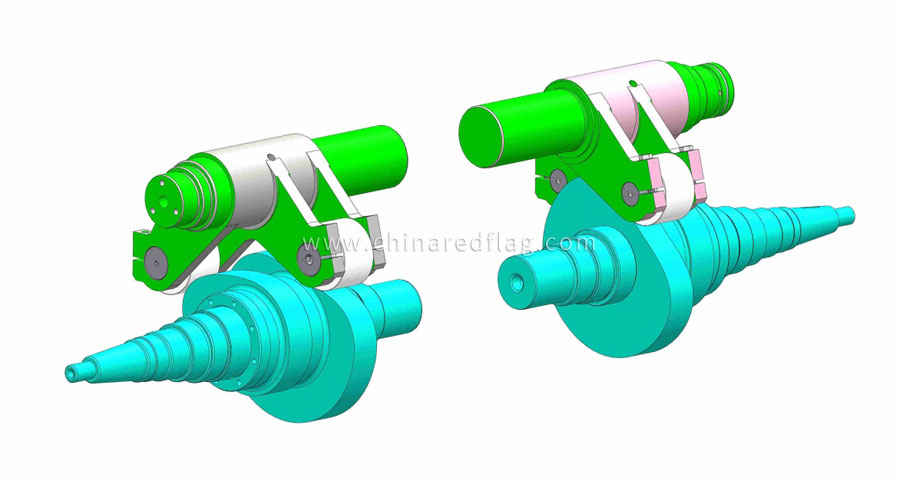

2. Technology innovation with conjugate cam beating as the core realizes high strength no-gap weft beating, reduces the generation of stop mark, and at the same time achieves longer weft insertion time (relative increase of 30%), smaller opening (reduce the shedding opening motion of the heald frame by 20%), lower air pressure high speed weaving, high speed energy saving significantly (up to 15%)!

3. Beating strength increase The middle U-shaped support arm is used for segment beating, and both sides of the beating shaft have counterweight balance. The aligning bearing support seat replaces the original bearing bush support, eliminates the beating gap, has stronger beating force and smaller vibration, and adapts to the heavy and high quality fabric.

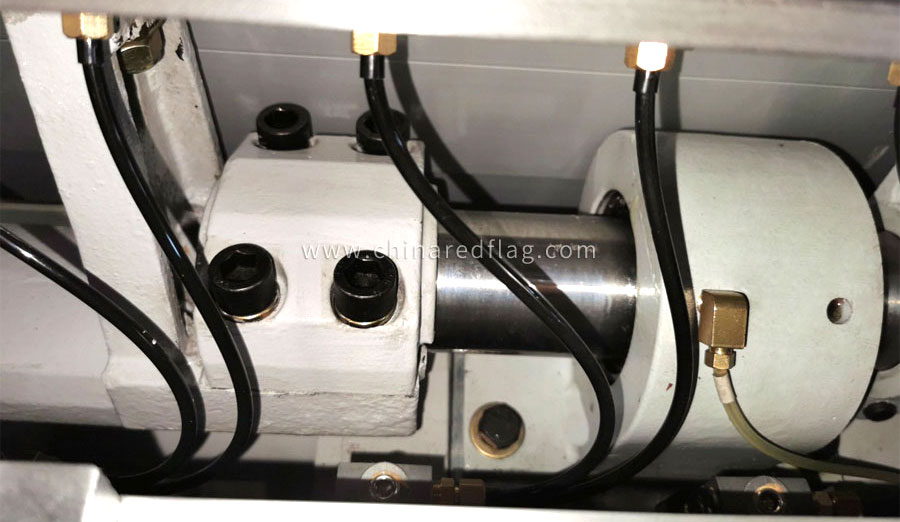

4. Active supply type oil bath lubrication, independent motor drive oil pump lubrication system, to ensure that the main box inside bearing, cam roller joint surface, roller interior and other running parts, have been well lubricated before running; The circulation of lubricating oil in the external tank and pipeline achieves the effect of heat dissipation, cooling and filtration, realizing the maximum reduction of wear. and convenient use and maintenance!

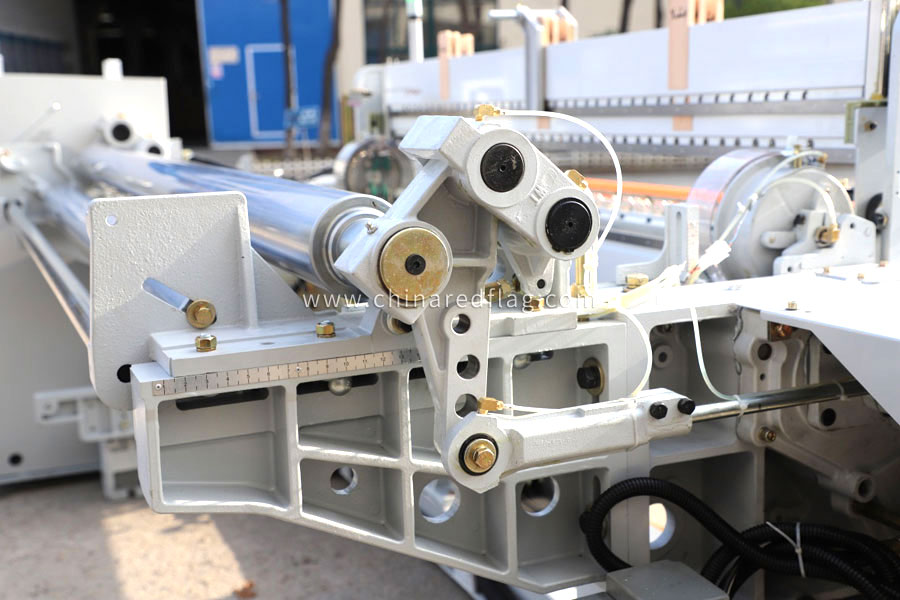

5. Enhanced external positive loosening rear beam The roller part of the loose swinging rear beam has extended to the middle of the front and rear sliding frame, which enhances the rigidity of the swinging beam and improves the weft beating force; The support seat of the rear beam is fastened from two linear points to four surface connections to reduce the shaking of the support under greater weft beating force. Loose warp swing arm support is more reasonable, reduce the distortion of large tension swing arm, improve the support strength of the rear beam; positive loose warp drive adopts stepless adjustable eccentricity, convenient variety change adjustment.

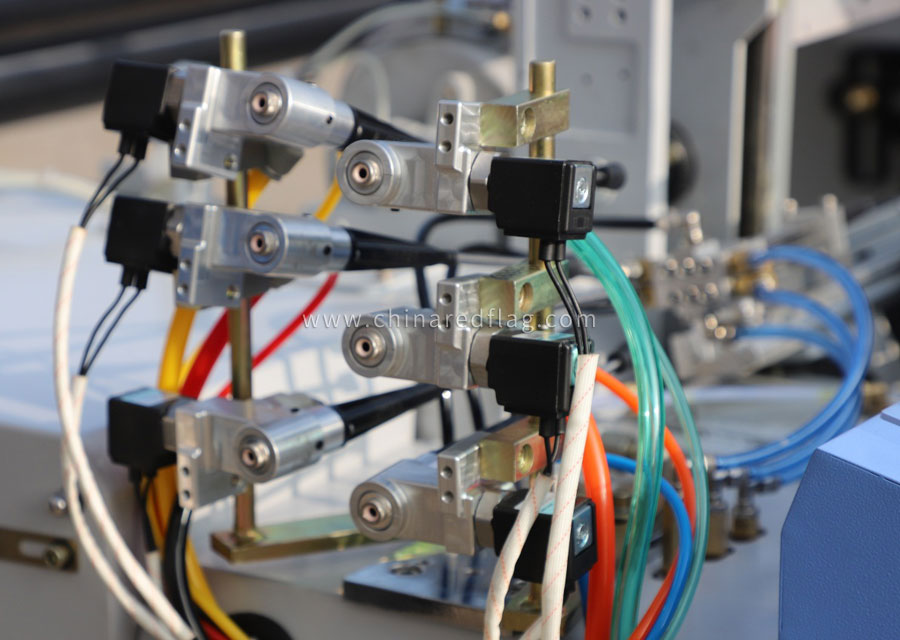

6. Directly connected auxiliary main jet nozzle and solenoid valve as a whole, reduce the original intermediate connection pipe, air flow control is more accurate, high speed performance and energy saving effect is obvious, can be equipped with double fixed main jet, enhance the weft insertion ability, control more intelligent, efficient and energy saving.

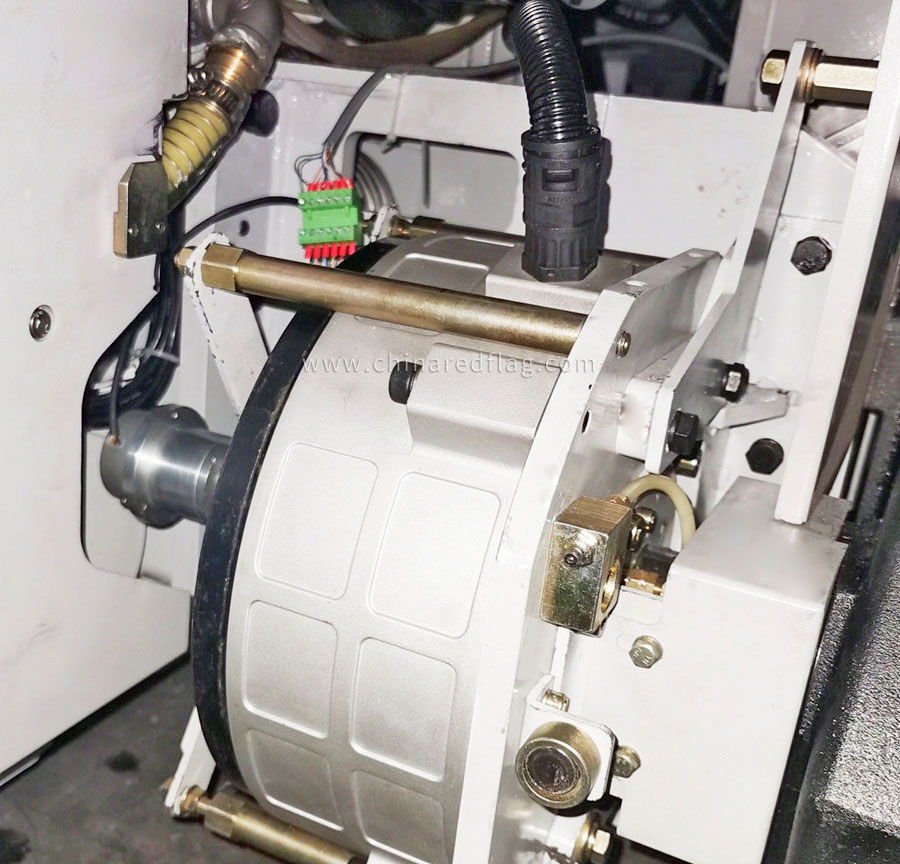

7. Shedding independent drive, fast independent picking function (optional) In addition to the conventional opening drive mode of synchronous belt drive, innovatively developed an opening mechanism driven by independent motor. The main motor and the shedding motor operate together, leaving out the synchronous belt or gear of shedding drive, greatly improving the running performance of the loom, and increasing the independent weft picking function, providing help in reducing the number of empty weft beating and reducing stopping mark defects.Compared with the mechanical weft picking of other looms, the independent weft picking shedding driven by an independent motor is faster and more efficient, and the failure rate is greatly reduced.

8. More convenient operation, more than 180 degrees open movable door on the left front with loom, convenient to adjust the air pressure, to ensure the overall appearance, occupy small space, easy to operate.

9. Rich configuration to choose, can adapt to different requirement :

1)Weft cutter: mechanical type, up and down electronic cutting type, front and back electronic cutting type;

2)Waste selvage cutter: mechanical type, electronic cutting type, hot melt type;

3)Cloth edge: planetary gear motion (high efficient buffering mechanical, electronic), leno doup;

4) Leno bobbin: ordinary leno bobbin, patent leno bobbin (bearing+ rubber sleeve);

5)Tuck-in: cut reed type pneumatic tuck-in, not cut reed type pneumatic tuck-in,mechanical tuck-in;

6) Independent selvage weaving: electronic independent selvage weaving;

7)Fell plate: segment type (electroplating), integral (aluminum profile + coated stainless steel) ;

8)Automatic picking remove (APR) : suction nozzle fixed, suction nozzle follow type;

9) Shedding: cam, dobby (16 or 20pcs), crank, jacquard;

10)Width: 130-460cm to meet the user variety of width requirements;

11) Main motor. super start motor (belt drive -slow group inverter) (optional independent inverter), direct drive motor (speed change)