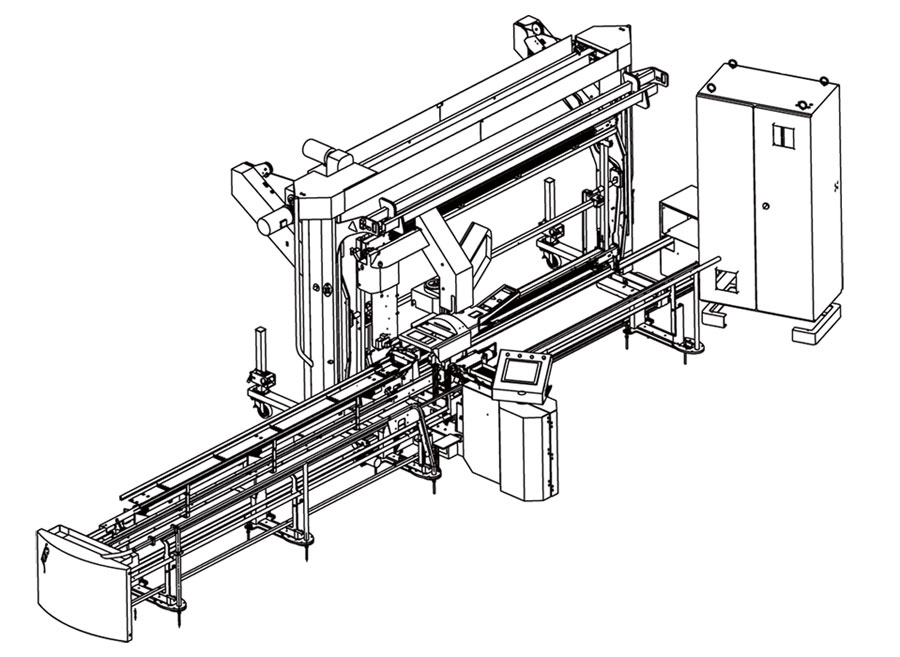

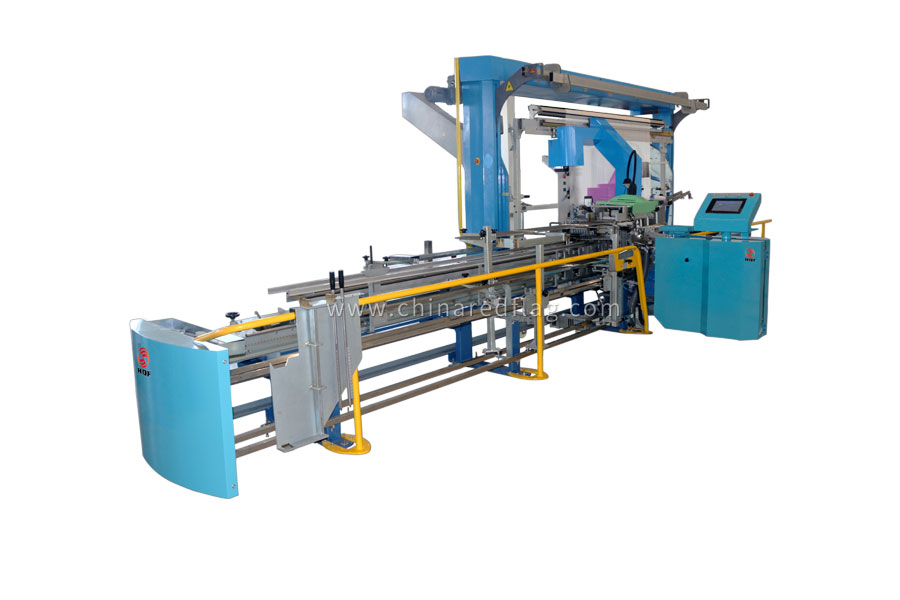

Our automatic drawing-in machine is modular designed, which speed is up to 165 threads per minute. Based on the standard model, there are multiple additional options available for customers.Maximum heald frames forO type is16 while forJ and C type is 20. It also comes with electronic double-yarn detection device, which detects double yarn and automatically stop without twisting. The situation of double-yarn reduces while cloth quality and production efficiency improves.

Drop wire module

The drop wires are provided by the drop wire storage, and the drop wire separator separates them in turn, then the cylinder gripper will bring it to the drawing-in position. After drawing-in process, the drop wires will be ejected and arranged on the drop wire rod.

Reed module

It is for conveying the reeds, and the clamp can stabilize the reed. The reed rack moves on the track during the drawing-in process, and the monitoring device checks whether its movement is in the right position. if it is correct, the reed knife will inserted to open the reed teeth to a certain width to make sure that rapier hook with yarn can pass through smoothly.

Warp module

The yarn will be separated by the yarn separating parts and then sent to the rapier hook. After passing through the drawing-in process, the yarn will be discharged from the rapier belt structure and then sucked by the yarn suction device. The yarn separation sensor detects whether the yarn has been correctly inserted.

Heald module

The machine obtains healds from the heald storage, and the separation knife separate healds and send them to the conveyor belt. After the heald threaded cross the hole in the right position, the heald will be discharged to the frame or by the arranger. The main frame or heald is mounted on the fixed frame.