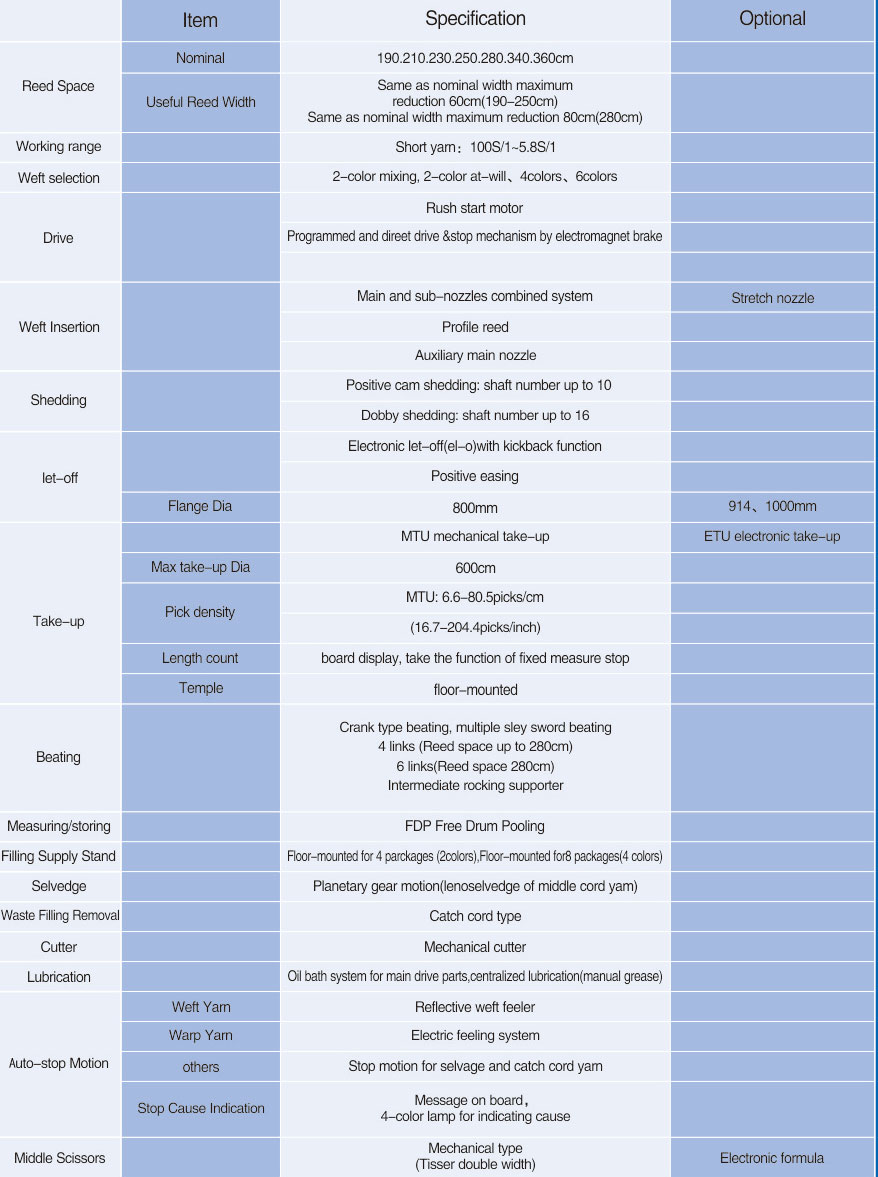

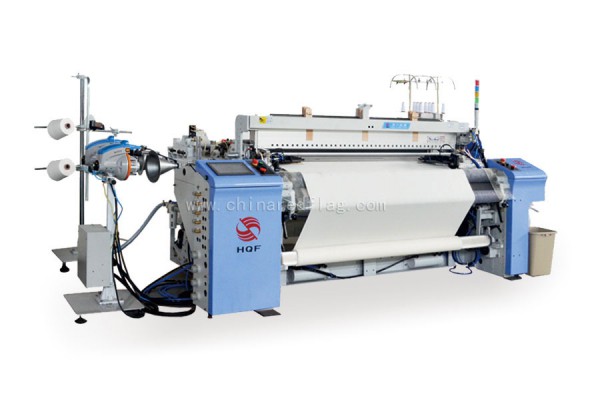

JA93 series Air Jet Loom is new generation of Qingdao Tianyi Red Flag,the company is well-developed after years of efforts made,its performance can be the first of today's international loom comparable.More reasonable frame and warp tension control system enables high-speed heavy woven fabric more stable weft insertion system more energy efficient.JA93 series jet loom will be its superior performance to lead the Chinese manufacturing industry looms.

1、The system features freely switchable high/low-pressure auxiliary air chambers to achieve independent pressure control for highly differentiated yarns while reducing air pressure loss.

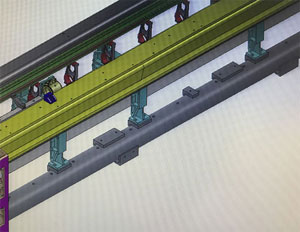

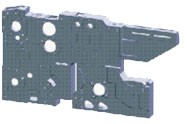

2、The integrated cloth rest (reed-probing type) features easy installation and reed width adjustment, with reed-probing capability that minimizes the distance between the fell of cloth and the rest plate for enhanced weaving stability.

The integrated cloth rest (reed-probing type)

3、Automatic Weft Replenishment System

4、Electronic independent selvedge device (crank shedding limits heald frame capacity but enables +2 frames for selvedge weave), (cam mechanism reduces cost).

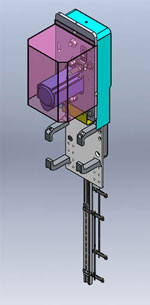

5、New super-stable rack

New rack connections increased rigidity,reducing rack deformation during

operation,and enhance the stability of the whole operation is more

suitable for high-speed heavy.

Achieve External easing drive,to facilitate the adjustment and maintenance;about through the tension sensing axis warp tension accurately transmitted to the tension control system;shortened tension Liang length,to prevent weaving heavy fabrics caused by bending of the width direction of the warp tension difference.

Changes need to be changed in the weaving varieties width,the structure can be easily adjusted on the right side brace,brace avoid truncation or replace cloth.