JA93T Terry air jet loom is a new generation of air jet loom product meeting the market demand by Qingdao Tianyi Group RedFlag Textile Machinery. which developed on the basis of our self JA93 air jet loom. Through a large number of market research, communicated with customers, in-depth analyzed, to meet the needs of customers by meticulous research and development. The design of JA93T terry loom shedding, weft insertion. let-off. beating-up. terry formation and take-up is improved according to the requirements of terry operation, making terry weaving more convenient and efficient. The product has the characteristics of high speed, high weaving efficiency. high automation and stable.

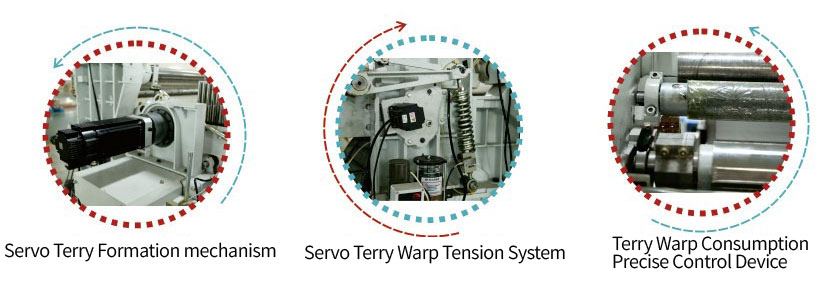

Servo Terry Formation mechanism

Terry formation mechanism is the core part of terry loom. We adopt

a new structure: using servo motor as terry formation motor,

cooperating with speed reducer to ensure the high efficiency and

stability of terry height. easier and more convenient for weaving

special varieties terry.

Servo Terry Warp Tension System

The terry warp tension of JA93T type terry air-jet loom is

controlled by torque motor, which controlling the forward and backward

movement of terry warping tension rod. The control system is not only

simple but also plays an important role in the accuracy of terry height.

Terry Warp Consumption Precise Control Device

In the weaving process of terry loom, the consistency of terry

height is an important standard for evaluating terry loom. terry Warp

Consumption Precise Control Device designed and developed by our

company. which obtained information fed back to the system. The amount

of terry warp used in weaving can be accurately calculated by adjusting

the system to ensure that the height of terry is consistent with each

time.

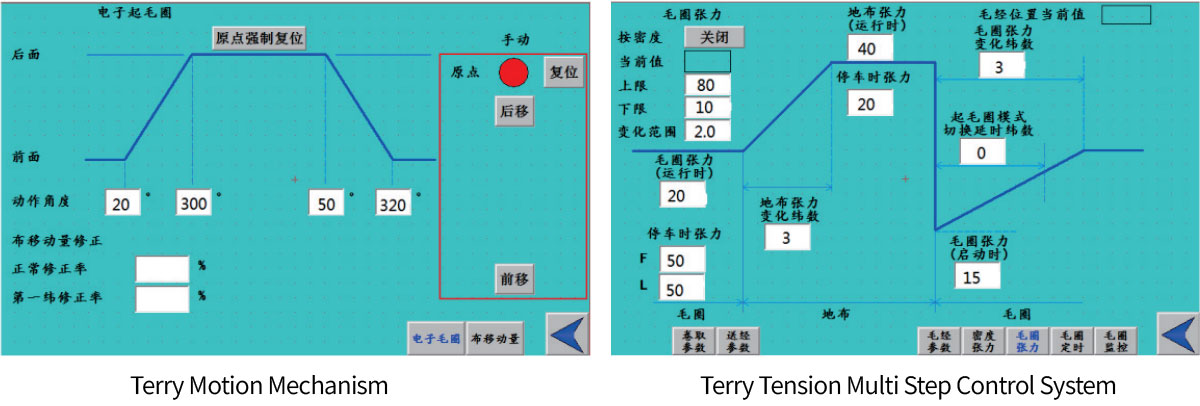

The JA91T Terry air jet adopts the electronic terry slider mechanism. The terry effect is achieved by controlling forward and backward movement of the sliding mechanism on the beam by the terry servo motor. Because of the electronic terry slider mechanism, the ideal terry action can be achieved by controlling the angle of slider accurately by the electronic control system, and this way is more accurate and convenient to adjust.

Terry Tension Multi Step Control System

Terry Tension Multi Step Control System can be used to set the terry warp tension in two stages (starting, running) while controlling the weaving ground warp or stopping. Thus, the terry height is consistent from plain fabric to terry. In addition, the system can set terry warp tension through density to realize the diversity of terry weaving.

| Item | Specification | Option | |

| Reed space | Nominal | 190,210,230,260,280,340(cm) | |

| Useful | Nominal space:-60cm~0(190~230cm) | ||

| Nominal space:-80cm~0(260cm over) | |||

| Weft selection | 2C,4C,6C | ||

| Driving | Starting method | Rush-start motor | |

| Motor power | Rush-start motor: 3.7kw (Dobby ) | ||

| Rush-start motor: 5.5kw (Jacquard) | |||

| Running operation |

Button two hands operation | ||

| Electro-magnetic brake to control loom stop | |||

| Weft insertion | Main and sub nozzles combined system | Stretch nozzle | |

| Auxiliary main nozzle | WBS | ||

| Terry specialized two rows profile reed | |||

| EDP | |||

| Beating | 4 links (narrow) 6links( wider) | ||

| Multi-braced solid beating shaft | |||

| Shedding | E-dobby: heald frames up to 20 | ||

| E-jacquard | |||

| Let off | Electrically controlled continuous positive let-off (up and down double beams) | ||

| Ground and terry tension multi step control | |||

| Terry precise length control | |||

| Ground dia.: Φ800mm, Terry dia.: Φ1000mm |

Ground dia.: Φ914mm, 1000mm, Terry dia.: Φ1250mm |

||

| Take up | ETU(Multi density, stop, no-weft) | ||

| Pick density: 23~300picks/inch | |||

| Woven precise counter, as per terry number doffing. | |||

| Max dia.: Φ600mm(in-loom) | Off-loom(Φ1500mm) | ||

| Weft supply stand | Floor mounted for 8 packages (4colors) Floor mounted for 12 packages (6colors) |

||

| Terry mechanism | Electronic terry slider mechanism | ||

| Servo terry formation | |||

| Fabric moving: 1~28mm | |||

| Selvedge | Planetary leno motion | ||

| Waste weft removal | Waste edge coiling drum type | ||

| Cutter | Left: Mechanical Right: Electrical | Left: Electrical | |

| Lubrication | Oil bath system for main drive parts, automatic centralized lubrication, manual grease | ||

| Stop motion | Weft stop | Optoelectronic weft feeler, double probe | |

| Warp stop | Electric two-rows two-sets contact device | ||

| Other | Stop motion for selvedge and catch cord yarn | ||

| Stop indication | Stop cause display in touch screen, multi-function 4 colors indication lamp | Photoelectric protect hand | |

| Control system | Multi-function control system, include parameters setting / control / monitoring / self-diagnosis / artificial intelligence interface | ||

| Inching by frequency converter( Forward and reverse) | |||

| Monitor output | |||

| Automatic air jet control | |||